|

BC2000 Motorized SMD Components Counter

Price(basic model): $2,194.50

|

Motorized electron-optical SMD components counter, works by detecting cut-out holes on SMD reel tapes, accurate and fast.

Features:

- Highly accurate, no counting

errors

- Can be used with any reel

tapes

- Forward or reverse counting, double check; Also count to preset numbers

- Max. tape diameter to 15", 380mm

- Fast. It takes about 100 seconds to count and rewind a full 0805 tape.

- Innovative external design to

view the counter readout and components on the tape at the same time

- Easy operation

|

|

Specifications:

- Counter: -59999 ~ 59999 pcs

- Size: 430 * 235 * 250 mm ( W x D x H )

- Weight: 9.5 Kg

- Tapes: All SMD tapes

- Print: Yes

- Missing

component detection: Yes

- Power: 110V or 220V, 60W

|

| Lead time about two weeks |

| BC2000 |

Basic model |

| BC2100P |

Basic model with printer |

| BC2100PS |

Basic model with printer and bar code reader |

| BC2100PT |

Basic model with empty pocket detection |

| BC2200 |

With all options |

|

|

Operational Instructions

|

|

1. Power the machine

After the power is turned on, the LCD displays:

SMD CHIP COUNTER

TTL-COU2000 |

and changes to:

YY MM DD HH : MM

20 04 12 03 14 : 30 |

followed by:

The startup self-checking process is finished at this time.

2. Keys and Settings

TIME key: Clock setting. Press this key shortly will display the date and time

on the LCD. Press and hold it for 10 seconds will switch to time setting

mode:

YY MM DD HH : MM

20 ** ** ** ** : ** |

Enter the current date and time. Press the TIME key again to exit.

POCKET CHECK key: Press this key will start the missing components detection process.

LCD will display a "@" symbol on the upper left corner. The machine

stops and beeps if it detects an empty position on the tape. Press this

key again will switch to normal operation mode. This function is available

only on BC2100PT and BC2200 models.

PRINT key: Print components quantity and current time. It can also print bar code.

This function is available on BC2100P, BC2100PS and BC2200. It only prints

positive numbers.

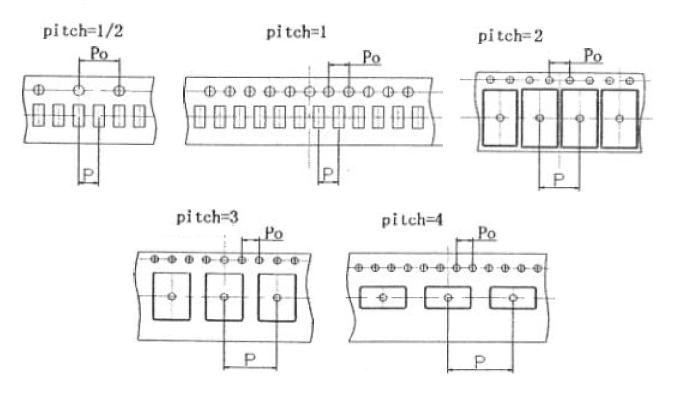

PITCH key: This key will set the tape pitch. According to EIA-481 standard,

available pitches(P:PO ratio) are: 1/2, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10,

11, 12, 13, 14, .... Press the PITCH key repeatedly till the LCD displays

the required pitch.

It can be seen that pitch equals the number of puncture holes between two

parts(gaps between two holes are 4mm on all tapes).

PRESET key: Press this key and enter the desired number, the machine counts to

this preset number and stops there. Press this key again will return to

normal mode.

DATA PITCH SET

00000 1 1234 |

Note: Preset value is invalid if >59999.

CLEAR key: reset the counter.

START key: start the counting. Motors start moving, the tape transfers from

one reel to the other.

STOP key: Stop counting.

REWIND key: Press this key rewinds the tape from the temp reel to the original

reel. The counter decreases at the same time. It stops when the counter

reaches zero. This also verifies the accuracy of the counting.

3. Operation

- Mount the reel to be counted on the left side. Make sure there is a temp

reel on the right side. Manually lead the tape through the counting gears.

Rotate the temp reel till the first component is aligned with the press

wheel.

- Set the pitch value as specified above.

- Press the START key to start counting. Note: the counter increases or decreases

no matter it is moved by the motors or manually.

- Remind the tape back to the original reel by pressing the REWIND key.

Rewinding also verifies the counting result.

|

|

|

|

SF-900 SMD Counter

Price(basic model): $1,485.00

- Automatic

- Derail protection

- Forward and backward

- Max. count: 50000

- Graphic LCD display

- Bar code option

- Size: L450xW180xH270

|

- All reel SMD parts can be used

- Tape width: 8, 12, 16, 24, 32, 44, 56mm

- Tape pitch: 2, 4, 8, 12, 16, 20, 24, 28, 32, 36, 40, 44, 48, 52, 56mm

|

Options:

|

Bar code reader |

|